How To Set Up Mig Welding Machine

How to Setup a MIG Welding Machine to Weld

Before setting upwards your machine you need to fix and research a few things earlier squeezing the trigger to striking an arc. Most of the weld quality relies on MIG welder settings or car set-up and proper preparation. Before setting upward you machine yous demand to get the answers to:

- What Type of Metal Will I Be Welding?

- What is the Metal Thickness That I Will Be Welding?

- How Will I Prepare the Joint?

- Do I Have The Correct Gas and Electrode/Filler Wire?

- How is the Welder Gear up-Up?

- Where Tin can I Find a MIG Welder Setting Nautical chart or Who Can I ask for Communication!

What Type of Metallic Volition I Be Welding?

The type of metal that will be welded has a large touch on the machine setting, electrodes and gasses that will be used. Different metals have different melting temperatures and concur that heat differently. When setting up you MIG welder y'all need to know exactly what type of metal you are going to weld. There is no single setting that works on every metal type. The 3 nearly commonly MIG welded metals are:

- Carbon Steel/Commonly Designated as A 36 Grade

- Stainless Steel/Nickel Based Alloys

- Aluminum/Not Ferrous Metals

What is the Metal Thickness That I Volition Be Welding?

The thickness of the metal has a major affect on the machine settings. When it comes to other processes like Stick or TIG welding you can utilise nigh the same setting for a diversity of metal thicknesses. For example y'all tin can weld ¼ in thick plate with the same setting used to weld a one" inch thick plate then on.

Now MIG welding on the other hand does not work this fashion! The heat settings vary greatly depending on the metal thickness. The biggest danger from a weld quality stand up signal comes from using as well low of a estrus setting. For example; in the Nuclear Power Plant building industry, MIG welding is virtually banned. This happened because in the past in that location were many welders who did not use enough heat and ended up welding joints that did not penetrate at all. The weld looks fine but a few taps with a hammer and the articulation falls apart. Fifty-fifty a proper spot weld would be a lot stronger! MIG welding too cold will put in the weld, merely it is only laying on the surface of the joint. To common cold of a weld is equally useful equally duct taping the joint.

How Will I Prepare the Joint?

Machine set-upward only works right if you take a properly set up-upwards articulation. Ideally yous want all rust, paint, oils, dirt'south and mill scale removed from the weld area. This is washed for 3 reasons:

- The first is a clean articulation produces a clean weld.

- The second is that the motorcar settings will vary between muddy joints and clean i.

- Finally a dingy joint volition spatter and spit increases the chances of you lot getting burns or starting a fire.

Exercise I Have The Right Gas and Electrode/Filler Wire?

A major part of setting up your auto is choosing the right gas and filler wire/electrode. This is an area that varies depending on all of the higher up factors and many more. The iii most commonly used gas/ electrode variations or combinations are:

- Carbon Steel – ER70s Electrode with a C25 Gas (75% Argon and 25% Carbon Dioxide)

- Stainless Steel – ER308L with a C2 Gas (98% Argon and 2% Carbon Dioxide)

- Aluminum – ER4043 with 100% Argon gas

How to Gear up-Up a MIG Welder?

There are three settings or controls that fix the welder and those three are:

- Voltage

- Wire Feed Speed

- Gas Menstruum Rate/Gas Type or Mixture

These three settings are what command the heat of the weld and depending what gasses are used the transfer blazon too. If you lot are not familiar with transfer types then please read up on MIG Welder Transfer Types considering they accept a large affect on your settings and how y'all will exist welding.

Newer machines like the MillerMatic 211 beneath no longer need to control wire feed speed and voltage. You just turn the punch to the thickness you want to weld and tweak it from at that place. The machine does everything merely regulate gas flow.

Voltage Settings and Polarity Blazon

To start the voltage type used is almost always D/C electrode (+) positive. This means that the handle is the positive side of the circuit, or it may be said, the electricity flows from the metal in to the welding handle. This setting almost never changes and if you do demand to alter information technology so you need to unbolt the internal leads and flop them.

The voltage is the chief heat setting that get's changed depending on the joint, metal thickness, gas type and position of the weld. It does most of the regulation and is most ordinarily used to change the welder's settings. The voltage setting varies depending on what size electrode is used, how thick the metal is and what type of gas is used. Since MIG welders are CV or Constant Voltage ability sources, the voltage does non fluctuate very much when welding.

Wire Feed Speed

The wire feed speed regulates how much or how fast the wire is feed into the weld joint. Wire feed speed is regulated in IPM or Inches Per Infinitesimal. The wire feed speed also serves another purpose for regulating the amperage. When Stick or TIG welding, the chief setting is amperage, just it is the voltage that fluctuates depending on the arc length. With MIG it is the voltage setting that stays the aforementioned but the amperage is changing depending on the wire feed speed and electrode stick-out. Picture this; the faster the wire is feed into the joint, the better contact it has. The meliorate contact, the more amperage gets through the wire and the higher the heat.

Gas Catamenia Rate/Gas Type or Mixture

Finally the gas type and gas menstruum rate help regulate the transfer type. A loftier percentage of Argon or Helium added to a mix creates a hotter arc. The primary goal of the gas setting is to provide enough gas to shield the weld area from the air. Gas flow rates are regulated in CFM or Cubic Feet Per Minute. This is an expanse that requires experimentation. In a shop setting a rate of 15 CFM may exist enough, but a drafty area might require a rate of 50 CFM. Another thing to sentry for is not to have the gas setting to high. A flow rate that is likewise fast tin can cause turbulence and suck in air to contaminate the weld. Having the right gas menses rate is a trial and error process that is ultimately a search for a happy medium of all settings in the current welding weather condition.

Putting the Voltage, Wire Feed Speed and Gas Menses/Gas Blazon All Together

Finally once these settings are all put together it produces the transfer type nosotros wanted and information technology has enough heat to properly penetrate the metal without burning a pigsty through the articulation. It is the result of trial and error that experimentation ultimately sets the machine just right to produce the weld we need, want or hope to brand. That all sounds fine unless a welding engineer or procedure has done all of that piece of work for yous. If not, then information technology is time to expect at the adjacent section; MIG Welding Charts, Settings and Guides.

MIG Welding Charts, Setting Guides and Exact Answers

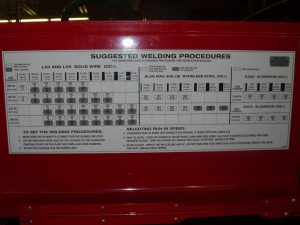

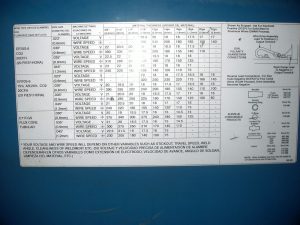

Finally if yous need some verbal answers and guidance then you lot tin read this! The manufactures of most welding machines include either a MIG welding nautical chart inside of the machine or a guide to their machine settings. I do want to mention that two identical welding machines that are made by the same company at the same time never run the same. These are only guidelines and do modify from machine to car! Each motorcar is calibrated differently and that all depends on its apply and who has serviced information technology.

MIG Welder Settings Charts, Guides and Tables for Steel, Stainless and Aluminum

To start the pictures above and below are the manufacturer's recommended (Lincoln Welders and Miller Welding Equipment) voltage, wire feed speed settings and gas recommendations. Afterwards those pictures I take added a nautical chart of my own settings (working on it) that are the happy medium of the manufacturer's recommendations. Just remember these are but guidelines and each automobile runs differently. This is a game of trial and mistake that requires just that, trial and mistake! Exam your settings on a piece of fleck metallic that is very close to the thickness of the metal that you will be welding. It should also exist set in the position that you will exist welding in. If you lot accept your time post-obit these steps so you will have a much easier time welding!

A Special Note to Student Welders Learning How To Set Your MIG Welder

You need to learn how to SET YOUR OWN Auto PROPERLY!Don't expect the student in the adjacent booth to do your chore or someone who welded on that machine earlier you! Information technology is piece of cake to come to a machine that is ready upwardly properly and take over! Almost jobs do not let you exercise that! Moving-picture show this; you lot drive 10 hours and blow at least $400 to accept a weld test! At present you might have some serious skills, but…. Oh, Oh! You accept no clue how to set upwardly your MIG welder! You will not only fail your test but likewise lose the money y'all spent to get to chore site. Companies desire real welders that understand their arts and crafts! You need to practise setting up many dissimilar welders for different types of welding.

How To Set Up Mig Welding Machine,

Source: https://gowelding.org/welding/mig-gmaw/settings-charts/

Posted by: balderastheassy.blogspot.com

0 Response to "How To Set Up Mig Welding Machine"

Post a Comment